ROOM’s Director of Design & Innovation Alejandra Albarrán led the 2-week turnaround to design a shield of protection for hospitals.

I’ve designed plenty of things over the years, from clothes and workspaces to ROOM’s soundproof phone booths. But earlier this month, I found myself working through the design needs of something entirely new: medical equipment. In just two weeks, our team developed the design and manufacturing protocols for a testing booth for COVID-19.

We all have witnessed firsthand how the coronavirus has crushed our world— lives lost, jobs lost, illness, economic hardship and a medical community that’s been overworked and overrun by the pandemic. This is especially true in New York City, a place that ROOM calls home.

Like most companies since the lockdown, ROOM employees have been working from home. In these unprecedented and chaotic times, we wanted to do something that could make a difference. So, we decided to use our resources – creative, manpower and material, to create a product that could aid healthcare workers in the fight against COVID- 19.

We already know the lives of healthcare workers are at risk every single day because of widespread infection and the lack of personal protection equipment. These are the people on the frontlines of the virus, people who are providing vital protection to us as a society. We need to figure out a way to protect them, too.

Because we wanted to make sure whatever we created would indeed actually help, we decided to use a one-week-sprint to investigate, talking to experts and practitioners in the medical care field and listening to their stories. Along with the clear lack of masks and ventilators, the resounding response from hospitals was that workers needed more physical protection when conducting tests.

That, we decided, was an area in which we could help. Our company had 940 plexiglass panes sitting in our factory—materials used to build the doors of our soundproof phone booth. We knew that this type of plexiglass material could be ideal to use as a medical shield; it’s lightweight and easy to disinfect.

Our co-founders, Brian Chen and Morten Meisner-Jensen, quickly pulled together an emergency task force across the company—comprised of engineering, supply, logistics, and marketing—and we set out to create a testing booth that could bring the much needed physical protection for medical professionals who were caring for infected patients.

We had some key parameters: The testing booths had to be modular, with a possibility of being daisy-chained to create an extended barrier. They had to be easy to clean. And they needed a design that could be broken down, shipped flat and easily put together on site. Hospitals don’t have time to set up complicated booths. They need something you can install in less than 30 minutes. The testing booths also needed to work in a multitude of environments—from indoor medical facilities to temporary outdoor testing sites.

Together, John Hwang, an industrial designer here at ROOM, and I found inspiration in a concept developed by medical researchers in South Korea, as well as designs used at Brigham and Women’s Hospital in Boston.

The Test Booth came together quickly—two weeks from concept to manufacturing and shipment—and it involved plenty of planning and logistics, as well as supply chain, engineering and design tweaks. Engineers figured out how to build the booth so it could lay flat when shipped and be put together quickly on site. Our supply chain leaders ensured we had the necessary elements in the factory to ship on such short notice, and logistics managers made it so we could get the booths out the door quickly to different hospitals around the world. Meanwhile, our marketing team developed a 360-degree campaign in just a few days to spread the word globally, and secured partnerships with top tier hospitals around the world to offer our first production round of booths as donation.

It was a massive collaborative effort to get this out the door, and it made me feel very proud to be part of a company that could successfully realize a project of this proportion.

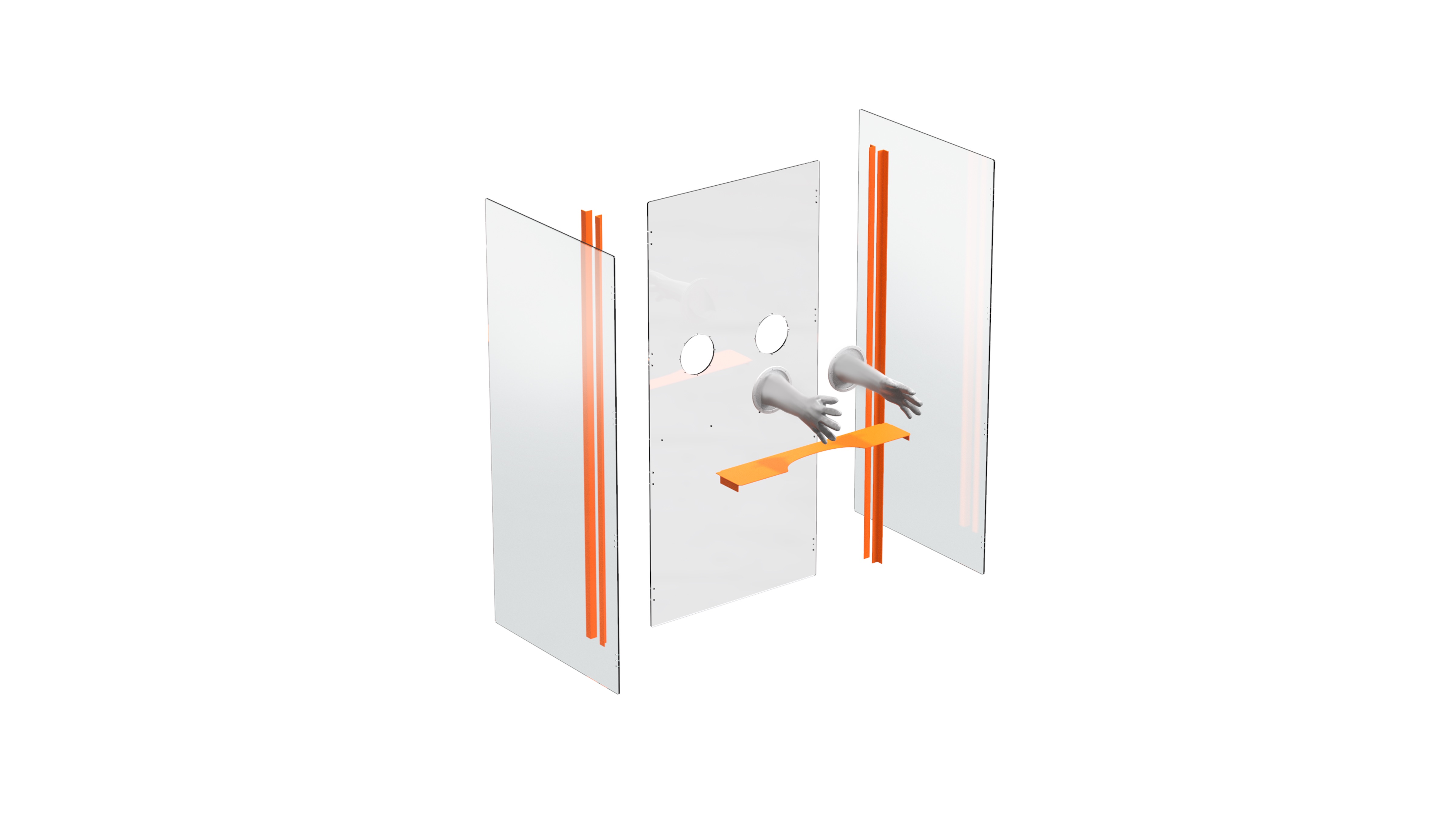

The Test Booth is constructed from three panes of plexiglass, upcycled doors from ROOM’s core product—the soundproof phone booth—providing a shield for frontline workers from the most direct form of exposure.

The rigid plexiglass is easy to disinfect and clean between patients. The sealable gloves are made from high quality neoprene that’s resistant to vapors, gases, and a broad range of chemicals to protect hands during testing.

The medical professional stands on one side of the booth and slips their arms into the attached testing gloves, while the patient enters the booth from the opposite side. The professional proceeds to take a sample. Once the patient has left the booth, both the gloves and the plexiglass booth can be disinfected prior to seeing the next patient.

Ten hospitals will be receiving our first set of completed booths in the next two weeks. Any hospital or healthcare facility can go to our website and apply to have a booth donated to their medical facility. Because of the demand, we have started fundraising for our next production run of Test Booths to ensure we can get booths to as many hospitals as possible, as quickly as possible.

For the first time in my career, I actually want people to copy our design. We made the conscious decision to open-source our design files with the hope that makers around the world will bring their personal passion and expertise to iterate upon the designs, and develop them in their local markets.

This pandemic has turned everything upside down and has dramatically changed how we live and work. But it has also called to attention the need to work together—and quickly—to come up with novel solutions to help in the fight against the virus. Using the talent and resources you have available, we invite you to launch your own sprint to help end the COVID-19 crisis. It doesn’t take extensive capabilities or backgrounds to make something happen—just a willingness to make a difference.